Warehouse operations face unique challenges during peak seasons, especially when increased demand coincides with higher temperatures. Whether driven by seasonal inventory surges, extended operating hours, or hotter weather, these periods can strain both facilities and staff. Temporary cooling solutions play a vital role in helping warehouses maintain productivity, protect inventory, and ensure safe working conditions when permanent HVAC systems are pushed to their limits.

Understanding how temporary cooling supports warehouse operations during peak seasons allows facility managers to plan ahead, reduce risk, and keep operations running efficiently.

Rising Temperatures and Increased Operational Demand

Peak seasons often mean longer shifts, higher staffing levels, and continuous equipment use. Forklifts, conveyor systems, packaging machines, and lighting all generate heat, which can quickly raise indoor temperatures. In large warehouse spaces, heat buildup is difficult to manage, especially when air circulation is limited or when loading docks are frequently open.

As temperatures rise, the working environment can become uncomfortable or even unsafe. Excessive heat affects employee performance, increases fatigue, and raises the risk of heat-related illnesses. At the same time, higher temperatures can impact equipment efficiency and reliability, increasing the likelihood of breakdowns during the most critical periods of operation.

Protecting Inventory From Heat Damage

Many warehouses store temperature-sensitive goods, including food products, pharmaceuticals, electronics, and specialty materials. Even slight temperature fluctuations can compromise product quality, shorten shelf life, or lead to costly losses. During peak seasons, when inventory levels are at their highest, the financial impact of heat damage is magnified.

Temporary cooling solutions help stabilize indoor temperatures and protect valuable inventory. By supplementing existing systems, warehouses can maintain consistent climate conditions even during extreme heat or periods of heavy activity. This added layer of protection reduces waste, preserves product integrity, and supports quality control standards.

Supporting Employee Safety and Productivity

Employee safety is a top priority in warehouse operations. Heat stress can lead to dehydration, dizziness, and reduced concentration, increasing the risk of accidents and injuries. During peak seasons, when workloads are heavier and schedules are demanding, managing indoor temperatures becomes even more important.

Temporary cooling improves air circulation and lowers ambient temperatures, creating a more comfortable working environment. This helps employees stay alert, maintain productivity, and work more safely throughout long shifts. A cooler workspace also supports morale and reduces absenteeism during high-demand periods.

Relieving Strain on Permanent HVAC Systems

Permanent HVAC systems in warehouses are often designed for average operating conditions, not extreme seasonal demand. During peak periods, these systems may struggle to keep up, leading to uneven cooling, higher energy costs, or system failures.

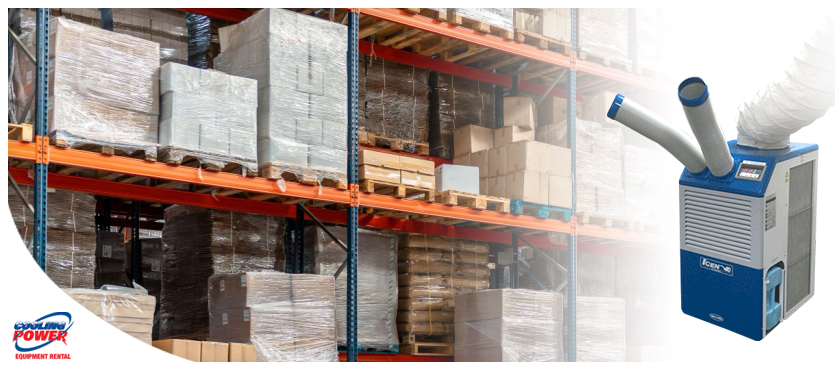

Temporary cooling systems provide relief by sharing the cooling load. Portable air conditioners, air handlers, and spot cooling units can be strategically placed to target hot zones or high-traffic areas. This approach prevents overworking permanent systems and reduces the risk of unexpected breakdowns that could disrupt operations.

Flexibility for Changing Warehouse Layouts

Warehouse layouts often change during peak seasons to accommodate increased inventory or new workflows. Temporary cooling solutions offer the flexibility to adapt quickly. Units can be repositioned as storage areas shift or as certain zones experience higher heat levels.

This flexibility allows facility managers to respond to real-time conditions without making permanent modifications. Temporary cooling can be scaled up or down based on demand, making it a practical solution for warehouses with fluctuating operational needs.

Maintaining Efficiency During Extended Operating Hours

Peak seasons frequently require extended operating hours, including overnight shifts. Cooling systems that perform adequately during standard hours may not be sufficient when running continuously. Temporary cooling helps maintain stable conditions throughout extended schedules, ensuring consistent performance across all shifts.

By supporting round-the-clock operations, temporary cooling reduces downtime, prevents equipment overheating, and helps warehouses meet delivery deadlines during critical periods.

Keeping Warehouses Cool When It Matters Most

Temporary cooling plays a crucial role in supporting warehouse operations during peak seasons. By protecting inventory, enhancing employee safety, reducing strain on permanent systems, and providing flexible climate control, these solutions help warehouses operate efficiently under pressure.

Cooling Power Corp offers temporary cooling equipment designed to support warehouse environments during high-demand periods, seasonal heat, and unexpected challenges. To learn more about cooling solutions that can support your warehouse operations, connect with our team here.