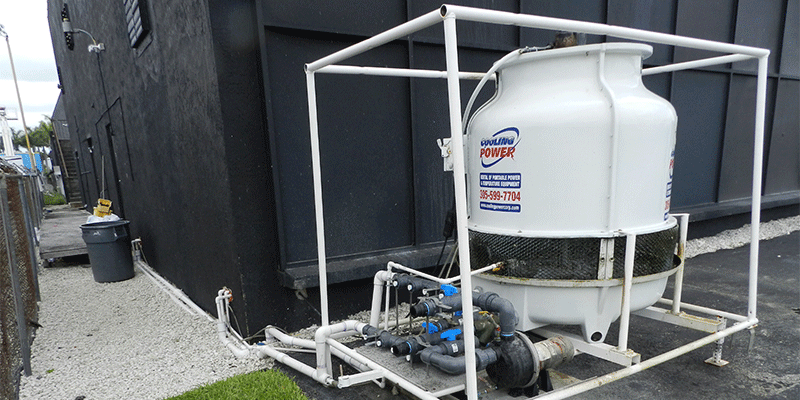

Modern day cooling towers are used to remove heat from a number of things, including machinery or heated process material. Our specialized cooling towers offer high-volume water-cooling through cooling pumps.

Cooling towers are heat rejection devices, capable of removing excess heat to the atmosphere by decreasing the temperature of a water stream. This type of heat removal is produced through evaporation. It allows a little bit of water to cool and evaporate into a moving air stream. The heat produced by the water stream is transferred to the air stream; as a result it increases the air’s temperature and humidity.

Cooling towers are often used to achieve lower water temperatures than an air-cooled or dry heat rejection device offers. Cooling towers may also provide a more energy and cost-effective solution. To help you envision what takes place, think of what happens when you throw water on a very hot surface. The water sizzles and quickly cools, rising up as evaporation. That’s why a wet surface provides much greater cooling ability than a dry surface.

A Closer Look At How Open Circuit Cooling Towers Operate

The first cooling towers were used in the 19th century; around the same time condensers for steam engines were invented. Condensers rely on cool water to condense steam released from the cylinders or turbines. As a result, backpressure is reduced, along with steam and fuel consumption.

An open circuit, or direct cooling tower, is an enclosed tower with a built in system that moves warm water to what is known as “fill”. This fill, also known as packing, provides an expanded interface where heating of the air and evaporation take place. Gravity causes the water to move back through the fill, and at the same time the water is cooled and brought into direct contact with the air passing over it. This cooled water pools in a cold-water basin positioned below the fill. It can be pumped back through the process to re-absorb more heat. The air that is packed with heat and moisture leaves the fill in such small quantities that it does not reabsorb back into the cooling tower.

Open Vs. Closed Cooling Towers

The term “cooling tower” is used to describe both open circuit and closed circuit heat rejection equipment. Open cooling towers work by using evaporated water to remove process heat and cool the working fluid at or near the wet-bulb air temperature. Closed circuit dry cooling towers use air to cool working fluid to near dry-bulb air temperature. The main difference is that cooling fluids are kept in a closed circuit that does not directly come into contact with the atmosphere or the re-circulated external water.

Closed cooling towers do not involve direct contact of the air or fluid. Indirect cooling towers rely on two different fluid circuits. One of which is an external circuit that allows the water to recirculate on the outside of the second circuit, which is made up of closed coils, or tube bundles, that cool hot fluids and return them to the closed circuit. As water flows over the outside of the hot tubes, it causes air to draw in and produce evaporative cooling comparable to open cooling towers. The heat moves from the internal fluid circuit to the tube walls of the coils, and to the external circuit. Throughout this process, the air temperature increases and some of the water is evaporated into the atmosphere.

Important Cooling Tower Terminology

Blow-out: This defines when water droplets are blown out of the cooling tower through the air inlet openings by wind, splashing, misting or other forces. There are certain devices you can implement that reduce water loss, such as windscreens, splash deflectors, water diverters or louvers.

Blow-down: This defines the amount of water flow that is removed to maintain the accurate amount of dissolved solids and impurities.

Drift: When drops of water are removed from the cooling tower via exhaust air it is known as drift droplets. These have the same impurities as water entering the tower. You can add drift eliminator devices to reduce drift rate.

Plume: The plume is the stream of saturated exhaust air that exits through the cooling tower. In certain conditions, it’s possible for this to present risks associated with fogging or icing of surroundings.

Leaching: If you use a wood structure as your cooling tower you will face leaching, or the process in which wood preservative chemicals are lost to constant water movement.

Cooling Tower Sizes

Cooling towers come in a wide variety of sizes, from small rooftop units to large structures stretching as tall as 600-feet and as wide as 330-feet. Small cooling towers are designed to maintain just a few gallons of water per minute, which is supplied through small pipes commonly seen in residential areas. Larger cooling towers can cool as much as hundreds of thousands of gallons per minute. Large cooling towers get their water supply from big pipes that measure as much as 15-feet in diameter, more commonly seen at power plants and other industrial settings.

What Type & Size Cooling Tower Is Right For You?

Cooling Power is happy to help you identify the right cooling tower for your needs. Contact us today with any questions or for a free quote.